Lean Manufacturing

Step into our factory and discover the behind-the-scenes of our production.

- Home

- Lean Manufacturing

Our Factory Delivers It All

Expertise. Efficiency. Quality.

Our facilities covering 8,000m² with 6 advanced production lines, producing 350,000 units of water dispensers annually. We rigorously adhere to ISO 9001, 14001, and 18001 standards to carry out the production steps of each product, and all employees undergo professional training in quality control to maintain product reliability. Our CNAS-certified laboratory provides precise testing and verification, guaranteeing top-tier product delivery.

Copper

Our faucets, crafted from premium copper, meet stringent water quality standards with 4-5 unique in-house designs.

Compressor

Certified compressors ensure efficient cooling and feature ETL and R290 CB, CE certifications.

Electronic Control System

Self-developed system combines mechanical and electronic controls, offering dual assurance for stable product performance.

Electronic Components

Selected per country standards: UL-certified for U.S. (5VA fire resistance) and TUV for Europe.

Food-Grade Materials

All water-contact materials, including tanks, pipes, liners, and fittings, are made from food-grade materials.

Heating Materials

Specialized cast aluminum heating materials with tightly controlled density, meeting RoHS environmental standards.

Precision and Care in Every Manufacturing Step

01

Material Selection

02

Welding

03

Compressor Assembly

04

Base and Fan Assembly

05

Leak Detection

06

Control Board and Circuitry Setup

07

Quality Inspection

08

Packaging

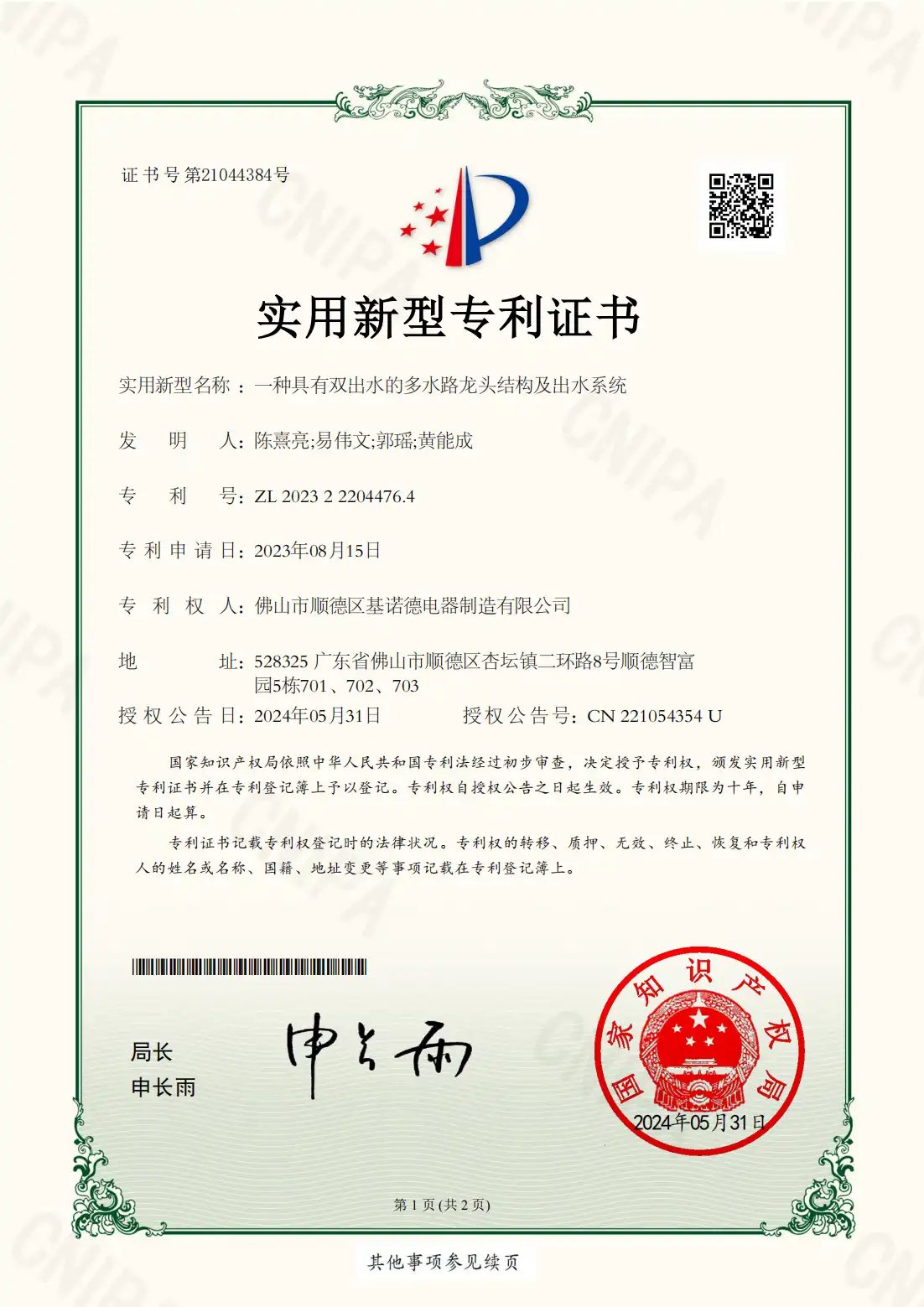

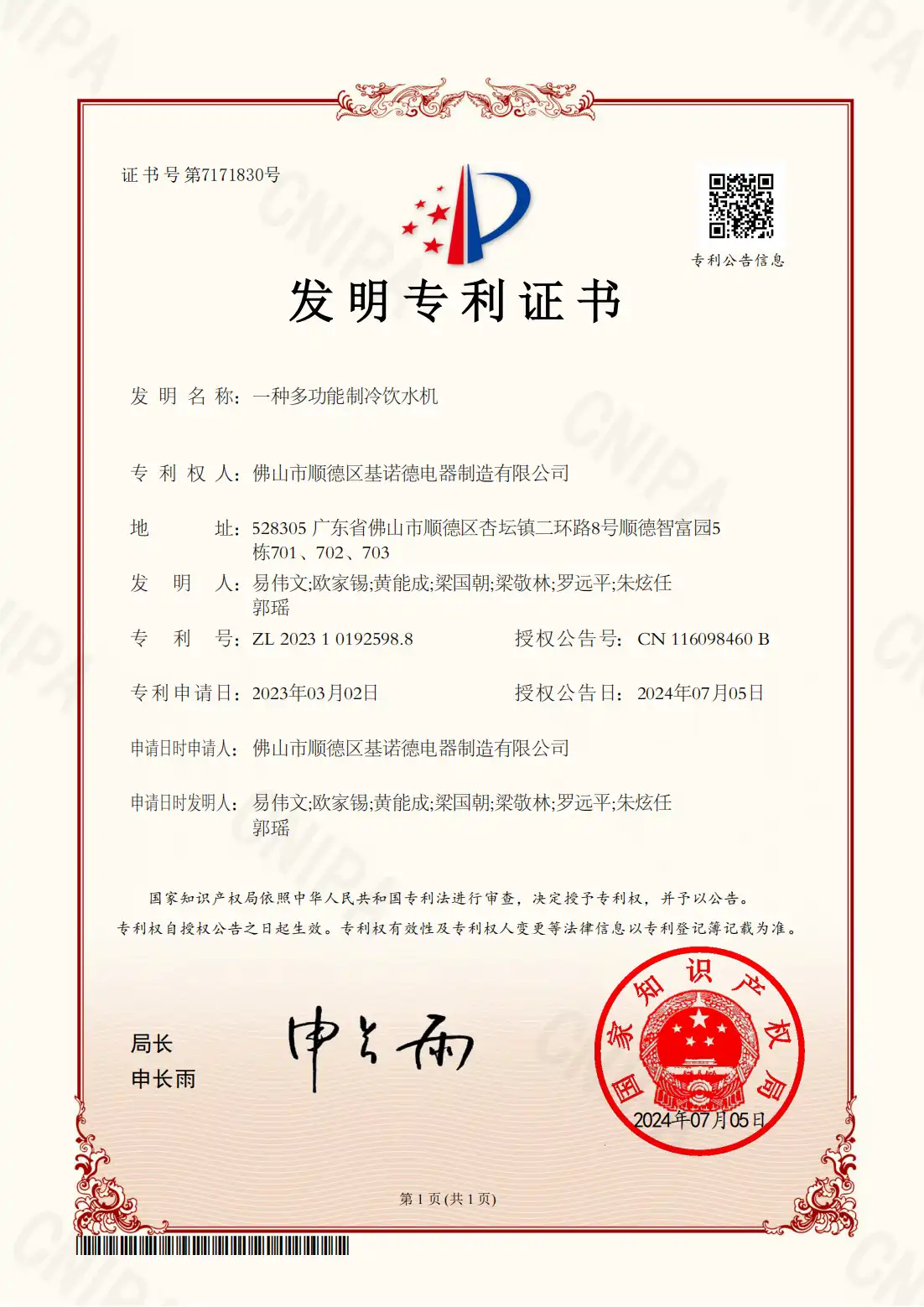

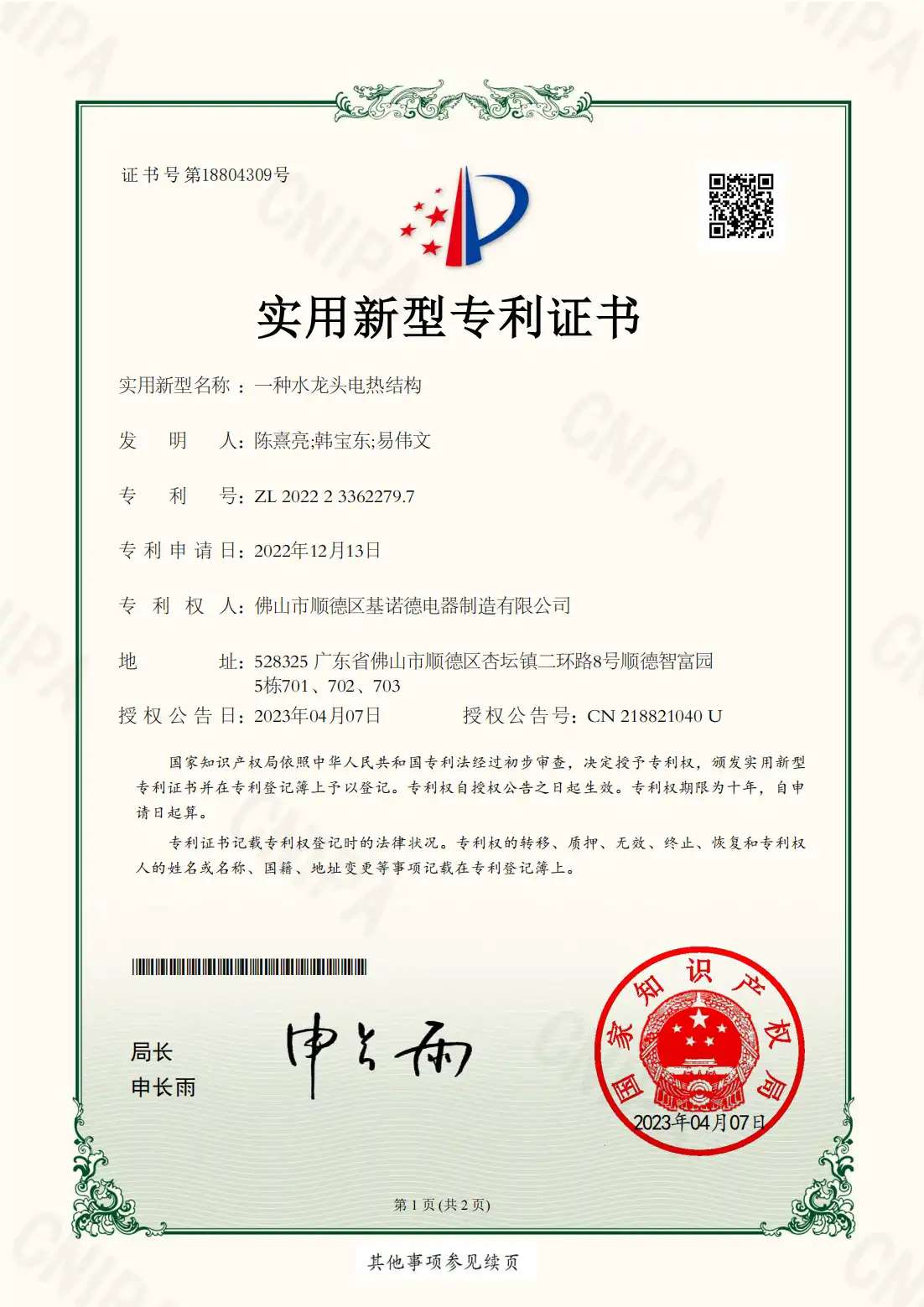

Our Certificates: Proof of Quality

Each certification shows our commitment to delivering safe, reliable, and high-performance water solutions worldwide.

-外观设计专利证书_00.webp)

外观设计专利证书_00.webp)